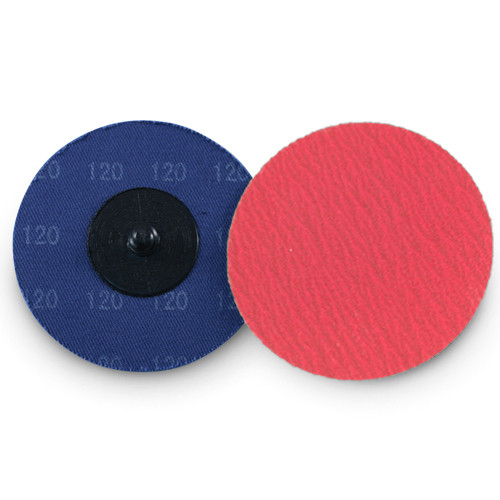

3" Quick Change Unitized Wheels

Black Hawk 3" Quick Change Unitized Discs are designed for effortless and efficient deburring, blending, cleaning, finishing or polishing in a compact size; ideal for work in confined spaces. Unitized wheels feature compressed, and cured layers of non-woven nylon fibers impregnated with abrasive grains. The structure of these unitized wheels allows for bi-directional use (they can be run in either direction), reduced loading, and minimal heat buildup which extends the life of the disc and protects the work piece. These unitized discs are less conforming than other surface preparation wheels to ensure a more consistent and uniform finish. Each quick-change unitized disc is constructed with a Type R, Roloc attachment to reduce changing time (Roloc TR, Lockit, and Powerlock III compatible.) decreasing work down time.

BHA Unitized quick change discs are available in a variety of combinations of densities, abrasive material, and grades including 2SF, 3SF, 2AM, 6SF, 6AM and 8AC. Please check the details below and select the unitized disc that best suits your needs:

Density = (2) low - (8) high

Low density wheels generate a more uniform finish and provide flexibility for finishing flat, contoured, or irregular surfaces without damaging the part.

High density wheels offer superior edge retention which helps maintain consistent shape and cutting action even during heavy duty applications. High density discs last longer, provide added rigidity and should be used for more difficult blending and deburring jobs.

Abrasive Material = (S) Silicon Carbide or (A) Aluminum Oxide

Aluminum Oxide is the most commonly used abrasive. Best suited for general-purpose deburring and blending, it is tough, economical and fracture-resistant. Commonly used on ferrous alloys and high-tensile materials such as: Soft Steels, Low Carbon Steels, Tool Steels & Other Ferrous Materials.

Silicon Carbide is a fast-cutting abrasive commonly used on low-pressure applications and on nonferrous metals such as: Stainless Steel, Titanium & Nickel Alloys, Aluminum & Non-Ferrous Materials

Grade = (F) Fine, (M) Medium, (C) Coarse

Abrasive Grade is important to the final finish of the product. Use a coarser grade for removing large amounts of material over a larger contact area. Use a finer grade on smaller contact areas where the final finish is important.

(SOLD INDIVIDUALLY)

Product Features:

• Premium compressed nylon

• Plastic roll-on backing (Type R)

• Perfect for tight work space

• Extra Thick 1/4" unitized material

• Load resistant

• Heat resistant

• Bi-directional

Applications:

• Polishing

• Buffing

• Finishing

Use on:

• Die Grinder

• Drill

• Air Grinder

(Needs Standard 3" Female Roll-On Disc Pad Holder)

Specs:

• Type R – Male Roll On (Equivalent to: Norton Speed-Lok TR®, Standard Abr. Lockit®, Merit Powerlock Type III®, 3M Roloc TR® )

• Dimensions = 3" Diameter (75 mm)

• Thickness = 1/4"

• Max RPM = 15,000

• Material = Compressed Non-Woven Nylon

• Variations = 2SF, 3SF, 2AM, 6SF, 6AM and 8AC Available